ADEPP Approach

ADEPP Decision Making Approach

For both new and existing hazardous industrial activities, management, regulatory authorities may make the decisions, or planning inquiries about issues such as:

- Whether measures are necessary to reduce its risk?

- How extensive the risk reduction measures need to be?

- Which of various options should be chosen?

- What level of safety management is appropriate?

Following approaches can be applied in risk reduction decision making process:

The decision-maker considers the range of possible actions, and select those, which they believe, are appropriate for the industry and the society.

The best available technology is selected, regardless of the risk reduction it achieves, and sometimes regardless of costs.

Measures are selected which conform to good engineering practice, according to relevant industry guidelines and codes of practice. Risk criteria approach, in which the results of a risk analysis are compared with numerical risk criteria. These usually indicate whether the risk are negligible, intolerable or in a grey area in between. If they are intolerable, the risk reduction measures must be adopted regardless of cost. If the risks are negligible then no further measures are needed.

Measures are selected if they have a favourable ratio of benefit (i.e. risk reduction) to cost (i.e. capital expenditure and operating costs). This is the most powerful and rational of the available approaches, providing objective guidance on specific risk reduction measure, while taking account of economic constraints. It is sometimes expressed as a requirement that risk should be "As Low As Reasonably Practicable" (ALARP). It is often included in the risk criteria approach and applied to the grey area where risks are neither negligible nor intolerable.

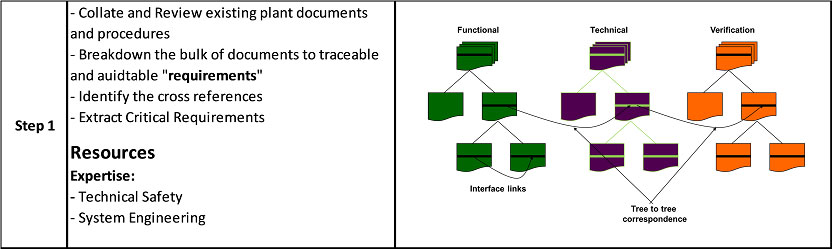

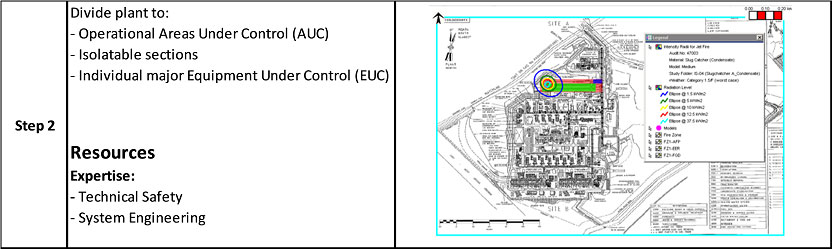

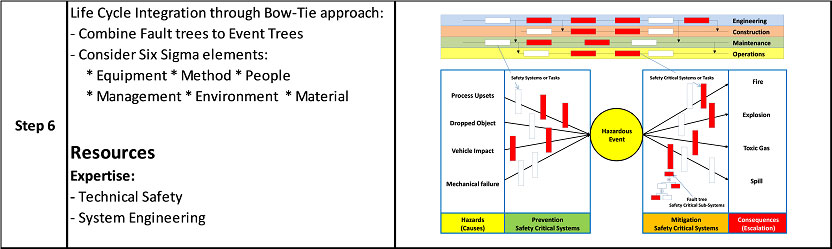

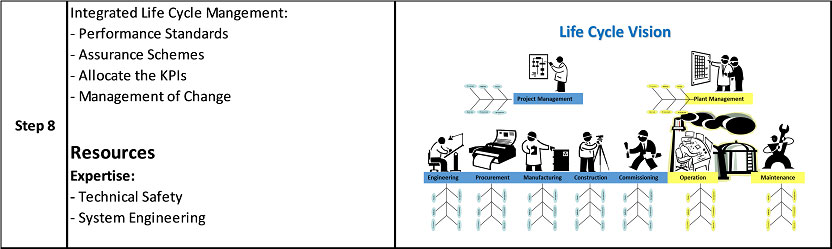

Each of the above decision making approach has its advantages and disadvantages. ADEPP™ is designed to optimise structure and guide all above risk reduction decision-making approaches. An event logic diagram is constructed and customised for each installation by close co-operation of ADEPP Academy and the client. This logic will be simulated in ADEPP package with pleasant and convivial interactive graphical interface. Then, AFR (Annual Fatality Rat e) can be applied as well as installation damages or a combination of both, for use in the critical safety systems testing process.

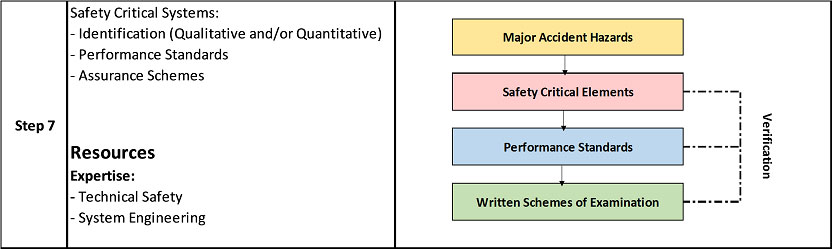

A critical safety system is defined in terms of the AFR as follows:

Any system, the failure of which, under the conditions of any given scenario, results in an increase in AFR of more than a given agreed percentage for the installation, is a critical system.

Therefore, the criticality of each system is determined in terms of its contribution to reducing the societal risk to the installation. This criticality test allows comparison between assumptions made in Qualitative and Quantitative risk assessment (QRA) of the installation with:

- The actual response of platform systems and personnel to the hazard scenarios

- As-built design information

- The current design of the installation will be confirmed as acceptable

- The system needs the particular improvement

- The new procedure should be identified

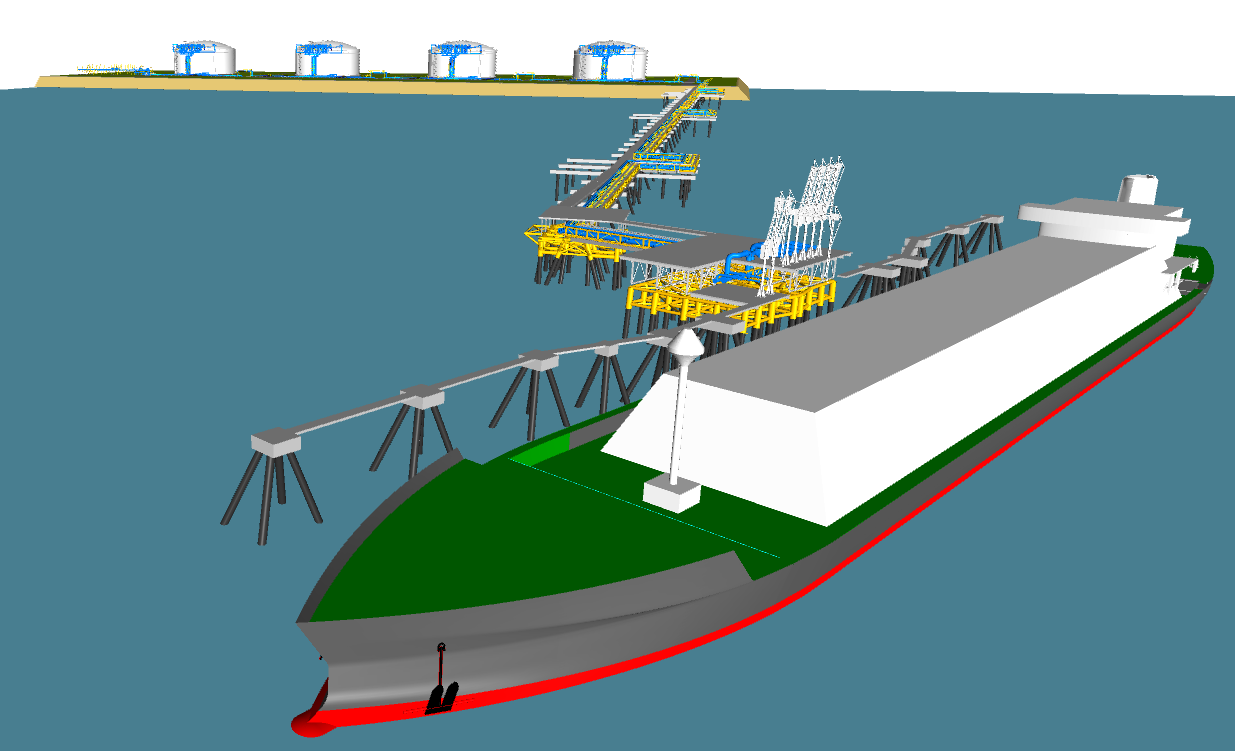

Integration with 3D Model |

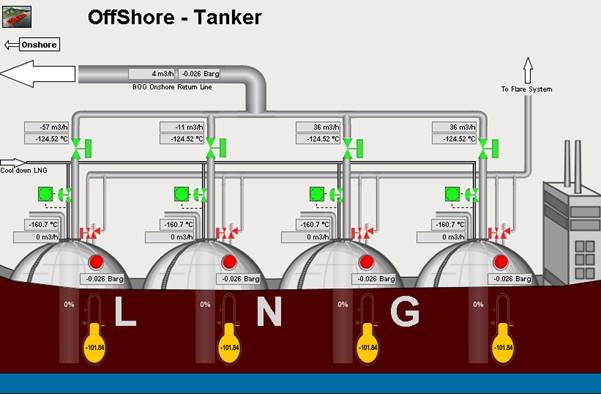

ADEPP monitor |

FPSO HSE-Toolkit |

Railway HSE-Toolkit |

Demonstration Version One - Click each image above for a quick download.